GRANITE

Granite is an igneous rock that’s commonly found in India made up of primarily quartz, feldspar, micas, amphiboles, and a mixture of additional trace minerals. These minerals and their variation in abundance and alteration give granite the numerous colours and textures we see in granite countertops. The word “granite” comes from the Latin granum, a grain. Granite is an igneous rock with between 20% and 60% Quartz by volume, and at least 35% of the total feldspar consisting of alkali feldspar, although commonly the term “granite” is used to refer to a wider range of coarse-grained igneous rocks containing quartz and feldspar.

Granite has become so popular over the last several years because it’s resistant to heat, water, pressure and is relatively low maintenance. Indian Granite countertops,flooring,elevation and other finishes can be found in most new home construction all over the world. Granite Colours range from pink to copper and green. There are literally hundreds of different patterns and colours to choose from. The south peninsula of Indian territories has great mines of high-grade Granite stones and Most reserves are located in the Indian states of Tamil Nadu, Andhra Pradesh, Jharkhand, Karnataka and Orissa.

GRANITE SLAB PROCESSING:

1.GRANITE MINNING FROM QUARRIES:

The extraction process of granite starts in Quarries, Granite blocks are obtained from special sites that are known as quarries. The first step of making a granite slab is to mine the raw granite materials out of the earth. Since granite needs to be extracted in large pieces, typical methods of large-scale blasting and collection will not work. Instead, Powerful machinery and explosives are used to mine granite out of the earth. This raw granite is extracted in blocks that are later shaped into granite slabs. Granite is one of the most popular types of dimension stone – stone that is quarried for the purpose of creating blocks or slabs. After quarrying, the blocks of granite are transported by truck to facilities that cut the stone into slabs of granite.

2.GRANITE BLOCK CUTTING:

Once a block arrives at a stone cutting (fabrication) facility, it is cut into slabs. To cut the block into even 2 cm or 3 cm thick slabs, it is run through giant saws that make many slices into the stone at once. These can simply have many large round blades side by side or diamond wire blades that cut through the slab like an egg slicer. It can take up to an hour for these blades to go through one foot of stone, The recent introduction of diamond wire cutting saws and other advanced technology to the industry have increased the speed and accuracy of this process, leading to more granite on the market and a less expensive finish products for homeowners.

3.GRINDING AND EPOXY PROCESS OF GRANITE BLOCK:

Once the granite is cut into slabs, it is sent to the grinding machine for grinding. This process not only smoothens the surface, but it also makes it ready for the next process epoxy application. After the grinding is done, epoxy resin is applied to the slabs to fill the pits and fissures.The proper combination of the colour of the granite and the epoxy it is paired with will also contribute in bringing out and highlighting the natural colour and pattern of the granite.The resin is then applied on the whole surface, and then reheated to ensure deeper penetration of the epoxy.

4.GRANITE POLISHING:

This is the final stage to bring out the natural colour and patterns of the granite slab with smooth surface to touch. This is done by running the slabs horizontally through slab polishing machines. These machines have large, diamond polishing pads that slowly bring out the shine in the stone with each new layer of polishing. Must like wood, granite much be polished with progressively finer pads to get a quality finish. This process just polishes the top surface of the stone, leaving the slabs with rough edges to be cut as per the sizes required.

TYPES OF GRANITE SURFACE FINISHES:

1.NATURAL:

The natural finish is basically the absence of treatment. The stone is sold as extracted from the quarry, once cut into the desired format. The final look depends entirely on the characteristics of the stone and its exploitation. This finish is appropriated for cladding and cobblestones.

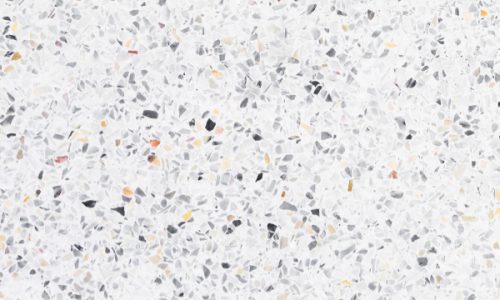

2.POLISHED:

A polished finish achieves a glossy mirror-like surface. This is the most popular type of finish for granite because it makes the full structure, depth, and colour of the stone visible with a reflective, shiny surface.

3. LEATHERED:

A leathered or brushed finish is a somewhat new finishing style that is becoming more popular. To achieve this finish, granite first begins with a honed surface. Diamond-tipped brushes are then run over the surface to add texture in the form of subtle dimples.

4.FLAMED:

This finish is achieved by exposing the surface of the stone directly to a high temperature flame. Flamed finish generates a thin roughness and protects the material for outdoor installation.

5.AGED:

This procedure is characterized by the use of constant vibration on the stone surface to simulate aging. Although different methods are used to achieve this finish, all generate soft surfaces.

6.SANDBLASTED :

This is similar to the bush-hammered finish. This finish is achieved by repeatedly blasting silica sand against the material through an air gun. Sand blasted finish generates very small craters that highlight the colour of the stone.